First of all, disclaimer:

I’m not responsible for any damage you may cause to your car or, even worse, to yourself using instructions provided bellow. I’m not a professional mechanic and what not, so use this at your own risk. Read entire post first and be sure you understand everything before you start it. If you’re in doubt – ask mechanic to do installation for you.

So, today I’ll show you how I installed:

- footwell lights

- LEDs in cupholder

- lighted door sills

These instructions are for Mazda 6i 2007 (Gen I) Sedan (they maybe applicable for other models of Gen I, but I can’t tell for sure). This is how it looks installed:

I will start with stuff you will need:

Major components – cold cathodes, LEDs, lighted door sills, tree-position switch.

You can get your cathodes here: http://www.oznium.com/ (amazing site with great customer service). You can get your LEDs there too, but I used another site for LEDs (and some other stuff): http://www.superbrightleds.com/ – this one, they have prewired LEDs, and housing for them, and lots of other cool stuff :). When it comes to door sills, you need to check eBay.

- Cold Cathodes (Blue, 12”, with transformers);

- Round Rocker Switch (three position, without LED);

- Prewired LEDs (get housing for them too)

- Door sills (this link may expire, so just look on eBay for best options/price)

|  |  |

|  |  |

Supplementary components (you might have them already :)):

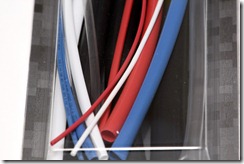

- Wire (red and black), 18 AWG (or 20 awg, but I used 18, and I got mine @ Radioshack);

- Add-a-fuse connector;

- Fuses (5A @ least).

- Butt and female push-on connectors;

- Heat shrinking tubes (for 18-20 awg wire, but I’d rather buy for variable size, because you’ll need some bigger ones);

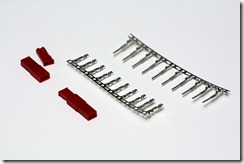

- JST 2 Pin connectors (male and female);

- Multimiter;

- Digital caliper;

- Crimping tool;

- Soldering stuff – soldering iron, solder, lead, etc;

- 1/4” and 3/4” hole bits;

- Small files (round one, at least, you’ll need it to clean holes);

- 3M double-sided scotch (2 rolls :), you’ll use it to attach door sills);

- 12V power source (I made my from old laptop power connector);

- Pliers;

- Set of screwdrivers (flathead and Phillips);

- Clamps (at least 10);

|  |  |

|  |  |

|  |  |

|  |  |

|  | |

|  |  |

Step 0 – Measure wires

I forgot to do that, so you’ll need to do that yourself (I mean I forgot to write down those numbers).

Step 1 – Creating wiring harness

Start with cathode transformers.

Remember: You can not extend wires that go between cathode and transformer (in fact, you can, and there are extension wires for this, but its not recommended, because cathodes will dim, or may not work).

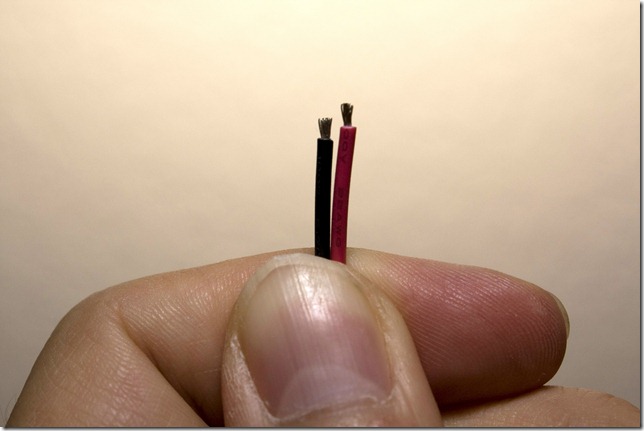

You’ll need ~5 feet of red/black wire (measure it by yourself). Solder your wires to respective transformer wires and cover with heat shrinking tubes.

Tip: If you don’t have heatgun, you can use your wife’s hairdryer :) (it works nice too).

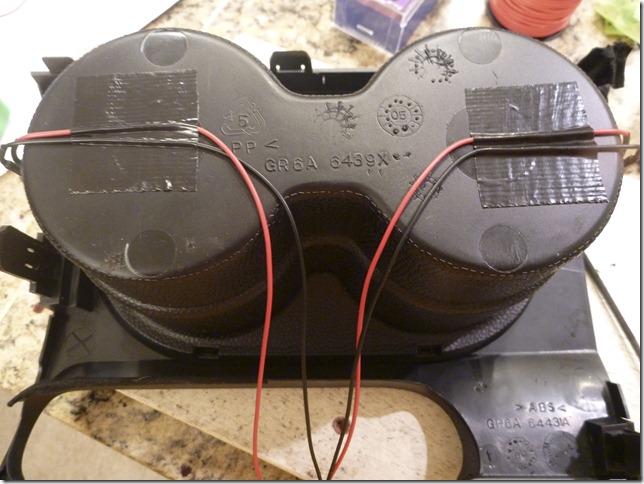

Repeat this step for all four transformers, but for cathodes that will go under front seats use shorter wire.

Test your wires (connect cathodes and connect them all to 12V source). As a rule of thumb, test connections you’ve made often, to uncover problems before its easy to fix them, and when everything installed.

Now, add JST connector (male) to the transformer wire. I decided to go this way because it simplified installation (and you can replace transformer later simply unplugging it from harness).

Now, add JST connector (male) to the transformer wire. I decided to go this way because it simplified installation (and you can replace transformer later simply unplugging it from harness).

That all for cathodes wiring preparation. Moving to the next step.

Step 2 – Install LEDs in cupholder (Requires drilling!)

OK, in this step you’ll need to drill 3 holes in cupholder: 1 for switch, and 2 for LEDs. If you don’t feel like drilling holes in your cupholder, well, you’ll need to find another place for switch and/or rework wiring diagram (comes later) for your needs.

Start with LEDs (and holes for them):

(LEDs on picture above is prewired and has a housing on it)

Cover places where you want your LEDs to be with some painting tape (it will reduce tear out).

Use 1/4” hole bit to drill holes in cup holder.

Since LED with housing is bigger than 1/4”, use a file to make hole a little bigger:

Now you can install LEDs in place and work on wiring. I soldered wires from both LEDs together and added a male JST connector at the end.

Use 3/4” hole bit to drill hole for rocker switch. Use a files to make hole a bit larger and add necessary notches (measure as you go).

Test your wires:

That’s all pre-wiring you’ll need for cup holder.

For door sills you don’t need any special wiring, just make sure they work.

By the way, my sills draw 80 mA of current (its important to know, because you’ll need to choose a fuse later):

Step 3 - Creating additional harness

You need a prewired add-a-fuse connector. See the pic below to get an idea how it should look:

(it has fuse in it)

Also, you’ll need these two connectors to connect to constant ground and variable (door) ground.

(Actually, pics a not up-to-date, and for the first pic you don’t need extra wire, and for the second one you’ll need ring connector for 12mm bolt).

And a final piece of the wiring harness – set of female connectors that you’ll plug your cathodes and cup holder LEDs into. Prewire 6 (one extra) female connectors, solder them together, and add some red/black wiring. I don’t remember how long that wire should be, but for red it should be enough to go from arm rest to driver side kick panel. And for the black – you need ~2 feet, from harness, to switch on a cup holder (and if you have your switch somewhere else, adjust wires appropriately).

|  |  |

Cover with heat shrinking tubes, and that all for this step.

Step 4 – Attaching door sills

Remove your plastic sills from a car, clean them up thoroughly. Add 3M double-sided tape on a plastic sill and add a lot of it on a metallic one. Use enough to level it with already attached 3M stripes (well, if yours come with 3M tape (but they usually do)).

(red – place where you need to add 3M tape, pic from http://home.online.no/~rekse/mazda6/gallery.htm).

Use clamps to hold sill in place, take your time.

Sill attached:

Before you start doing this for rear sills, you’ll need to bend them a little. Because they come straight, and plastic trill has some curved corners. Do it slowly and gently, take your time. It took me several hours in the evening to attach these (and I left them overnight with clamps).

Step 5 – Before you install.

Before you install, you need to choose a fuse for your new wiring you’re about to install in your car. Use your multimeter to check how much current it draws. Mine was 3+ Amp, so I took 5F fuse.

That’s all preparations you’ll need to do before you start installing it.

Step 6 – Installation (cathodes)

Before I start explaining how to install it in a car, here is a “wiring” diagram :)

As you can see, all cathodes are connected under arm rest. Power goes from fuse box, and they have 2 grounds, depending on switch position: constant ground (there is a bolt next to hand brake and variable ground, from doors). Sills has independent wiring (connected to fuse box and door ground, in one place).

Start installation by removing gear level cover (remember, cigarette lighter and lights are connected to it, so be careful. Use a small flathead screwdriver to unfasten cigarette lighter.

I recommend disconnecting your battery now (“-“ terminal).

Using 12 socket key remove nut displayed on pic below:

Attach following ground connector, and put nut back. This is your constant ground point.

Note: Clean up any rust under that nut, if you have any.

Start installing cathodes. Remove following two screws, that holds center panels in place, that will give you more freedom (those screws are covered with some caps, see pic below).

Install wiring harness. Make sure you have left enough wire under arm rest and there are enough wire to reach fuze box (red/black wire with white electric tape on it, electric tape is not required, but it tells me what wire is that).

Remove the glove box (its pretty easy, see my other post for details :)):

Attach cathode:

Connect cathode to the transformer. Attach transformer to “frame beam” (I don’t know what’s the name of that part, but you can get an idea from images below):

Run wires behind panels to the compartment under arm rest. Do same stuff for driver side cathode. I found a good place for cathode itself next to OBDII port.

Clean up driver side wiring (use cable ties to secure wires):

Next, install cathodes (and transformers) under passenger and driver seats. I attached cathodes as well as transformers directly to springs under the seats and run wire to the center console, under the arm rest, where all wires go. Make sure you run wires under the seat track, so you can move your seats and don’t run over wires and damage them.

Now, connect everything :)!

Look scary :). Now, cleanup! (Always secure wire, don’t left them hanging!).

Connect grounds to the switch and install cup holders in place (yellow/center connector goes to harness, left and right – “always on” and “on when map lights on”, or vice versa, depending on how you attach them):

And final touch for cathodes – pluging them to fuse box. You need constant 12V+, and you can use map light for that. Use your manual to locate correct map light fuse, remove it, insert into “add-a-fuse” connector, next to 5A fuse (it should be left most, and 5A right most), and insert “add-a-fuse” instead of fuse you removed. Connect power wire you run from harness to kick panel, secure everything in place:

That’s almost everything for cathodes. But now you can hook up your battery and test everything (put your switch to “always on”/constant ground position). Your cathodes and cup holder LEDs should work now.

I’ll explain how to connect to variable ground in next step (along with door sills installation).

Step 7 – Installation (sills)

Start by locating ground wire. For instance mine was yellow-black. How did I find it? I removed door courtesy light cover, bulb (LED, I installed recently :)), screw next to bulb socket. Then I inserted multimeter to find out which one is negative:

Then I looked to what wires its connected:

And this gave me yellow-black.

Now, you can install sills wiring, or simply connect variable ground from cathodes. Anyways, I cut the wires, and connected to it: cathodes ground, driver side sills connector, and next piece of wire that will go to driver side back seat.

Secure wires, attach sill and run wires to the back seat. Couple words about power: you need to attach to the same “add-a-fuse” connector, you’ve attached your cathodes to (check back the wiring preparation step, I made “V” connection for add-a-fuse, so both cathodes and sills wiring could same 12V+ source).

For the back seat installation you need to remove back seat first. There two locks under the seat, pull them and release the connector. Don’t forget to unfasten center seat belt :).

Connect door sill, and run wire to passenger side. There is a wiring goes under the seat, so you can use same route for your wiring:

Connect sills on passenger rear and then front sides. This is how connector should look like when everything is secured:

Install sills, clean up all the mess, connect your battery and enjoy!